(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

63,000 Stock items for Same Day Shipping

63,000 Item Stok untuk Pengiriman di Hari yang Sama

Search by Category / Brand

Pencarian dengan

Kategori / Merek

Search by Category Pencarian dengan Kategori

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

- Komponen Mekanis

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Sekrup, Baut, Washer, Nut

- Material

- Komponen Kabel

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Elektrikal & Kontrol

- Peralatan Pemotong

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Peralatan Produksi

- Penanganan Material & Penyimpanan

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Perlengkapan Keamanan & Umum

- Perlengkapan Sanitasi & Lab

- Komponen Press Die

- Komponen Plastik Mold

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Komponen Injeksi Moulding

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Brand Pencarian dengan Merek

This translation is a Google translation Terjemahan ini adalah terjemahan Google

- Sehubungan dengan adanya Peraturan Baru Kementerian Perdagangan No.36 Tahun 2023 tentang Pembatasan Impor Barang, MISUMI Indonesia melakukan tindakan pencegahan. Lihat informasi detailnya di sini

Due to New Regulation of Ministry Of Trade No.36 of 2023 concerning retrictions on imports of goods, MISUMI Indonesia do precautions measure. See detail information here - Nomor telepon alternatif Kontak Layanan Pelanggan : 021-29182911| 021-29182991 | 021-29182997 | 021-29182998

Alternative telephone number Contact Customer Service: 021-29182911 | 021-29182991 | 021-29182997 | 021-29182998

Shock Absorbers, Two-Way Type

- Volume Discount

Part Number

Configured Part Number is shown.

Shock Absorbers Product Overview

The economy series two-way type shock Shock Absorbers has a unique double stroke structure, effectively reducing the installation space and trial cost.

Its automatic compensation structure can produce a consistently soft Shock Absorbers effect.

The advantages of using shock Shock Absorbers:

1. Improve production efficiency: equipment can be operated at high frequency and high speed to improve production efficiency because the shock absorber can stop the impact object smoothly.

2. Extend mechanical life: the buffer can absorb the energy generated by the impact, greatly reduce the impact and vibration caused by the object to the machine, and avoid damage due to impact vibration.

3. Improve Shock Absorbers product quality: the buffer eliminates the shock caused by impact objects and the damaging impact, allowing the smooth operation of the machine and equipment, and improving the product quality.

4. Significantly reduce noise, and provide a quiet working environment.

5. Improve the safety of mechanical running.

Shock Absorbers Product Features

2. Miniaturized design and strong space adaptability.

3. Shock Absorbers energy smoothly and softly.

4. Abundant stock and fast delivery.

5. Long life with 800,000 times being used for reference.

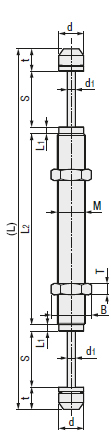

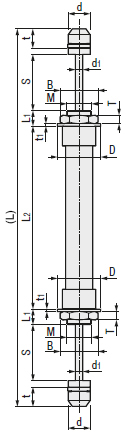

Dimensional Shock Absorbers Drawing

Specifications Shock Absorbers Overview

| Impact Speed Type | Maximum Collision Velocity | Operating Environment Temperature | Reference number of replacements |

| Two-Way Type | ~4.0m/s | -5 to 70℃ | 800,000 cycles |

■Shock Absorbers Material Table

Shock Absorbers Material Shock Absorbers Material | |

| Body | Cover |

| STKM11A | Urethane |

Surface Treatment Surface Treatment | |

| Threadless Type | Chemical Nickel |

| Fully Threaded, Semi-Threaded Type | Ferroferric Oxide Protective Film |

Example of Shock Absorbers Use

Example of Shock Absorbers Use 1

Precautions Shock Absorbers

| Coarse Outer Diameter (mm) | M8×1.0 | M10×1.0 | M12×1.0 | M14×1.5 | M20×1.5 | M25×1.5 | M27×1.5 |

| Tightening torque of nut (N.m) | 3.9 | 7.8 | 7.8 | 9.8 | 29.4 | 49 | 58.8 |

2. Shock Absorbers Pay attention to check whether the head circlip is off.

■ Overloaded buffer will cause abnormal increase in the internal pressure of the buffer tube, making the head circlip off, and internal parts may pop up and cause injury.

■ When the buffer with the head circlip is working, please keep your face and other parts away from it.

3. Please pay attention to the splash of the broken buffer head due to impact.

■ Overload use will cause damage to the head, resulting in injury.

■ It is recommended to install an anti-splashing cover.

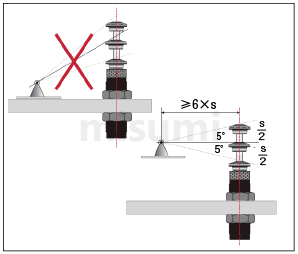

4. Please pay attention to lateral misalignment load and lateral misalignment angle.

■ When the lateral misalignment load exceeds ±2.5 degrees, it will cause piston rod bending, bad reset, and internal lateral misalignment friction, resulting in performance degradation and even product breakage.

Please aim at the center line of the buffer piston rod for impact. (If the lateral misalignment angle is greater than ±2.5 degrees, please use the angular misalignment Shock Absorbers (the range of lateral misalignment:± within 10 degrees)

5. Operating Temperature Range

■ Please use the buffer within the specified temperature range.

▪ Use outside the specified range will reduce the life of the seal packing and the pressure accumulating sponge, and cause the buffer to break.

6. Shock Absorbers Operating Environment Requirements

■ Please do not use it under medium or high pressure in a vacuum environment.

■ Keep the guide shaft clean, and avoid cutting powder, cutting fluid, water, etc. from being attached to the guide shaft, otherwise it will cause seal damage, oil leakage, poor buffer action, and buffer damage.

※ If you need to use it in the cutting fluid environment, please choose Misumi’s cutting fluid resistant buffer series products. See Misumi's official website.

8. Shock Absorbers To prevent the buffer from increasing lateral load, the distance between the installation position of the buffer and the fulcrum should be equal to or greater than 6 times of the buffer stroke.

And when the side load and the buffer center line form an angle of 5°, the Shock Absorbers energy is the maximum.

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| E-MSSTACD2035H |

| E-MSSTACD2035L |

| E-MSSTACD2035M |

| E-MSSTACD2045 |

| E-MSSTACD2050L |

| E-MSSTACD2050M |

| Part Number | Minimum order quantity | Volume Discount | Days to Ship | Stroke (mm) | Max. Absorbed Energy (J) | Max. Collision Velocity (m/s) | Thread Type |

|---|---|---|---|---|---|---|---|

| 1 Piece(s) | Available | Same day | 35 | 52 | 3.5 | Semi-Threaded Type | |

| 1 Piece(s) | Available | 10 Day(s) | 35 | 52 | 1 | Semi-Threaded Type | |

| 1 Piece(s) | Available | 10 Day(s) | 35 | 52 | 2 | Semi-Threaded Type | |

| 1 Piece(s) | Available | 10 Day(s) | 45 | 55 | 4 | Fully Threaded | |

| 1 Piece(s) | Available | 10 Day(s) | 50 | 60 | 4 | Fully Threaded | |

| 1 Piece(s) | Available | 10 Day(s) | 50 | 60 | 4 | Threadless Type |

Loading...

| NO. | Mounting Screw Nominal (M) | Stroke (S) | Maximum Energy Absorbed (E') | Maximum Equivalent Mass (me') (kg) | Maximum Collision Velocity (M/S) | Thread Type | Total Length (L) | L1 | L2 | T | t | t1 | D | d | d1 | B (Both sides width) | |

| Per Cycle (J) | Per minute (J) | ||||||||||||||||

| 2035L | M20×1.5 | 35 | 52 | 1030 | 650 | 1 | Semi-Threaded Type | 234.6 | 49 | 84 | 8 | 15.8 | - | - | 18 | 6 | 26 |

| 2035M | M20×1.5 | 35 | 52 | 1030 | 200 | 2 | 234.6 | 49 | 84 | 8 | 15.8 | - | - | 18 | 6 | 26 | |

| 2035H | M20×1.5 | 35 | 52 | 1030 | 40 | 3.5 | 234.6 | 49 | 84 | 8 | 15.8 | - | - | 18 | 6 | 26 | |

| 2045 | M20×1.5 | 45 | 55 | 2290 | 350 | 4 | Fully Threaded Type | 275.6 | 2.5 | 149 | 8 | 15.8 | - | - | 18 | 6 | 26 |

| 2050L | M20×1.5 | 50 | 60 | 2500 | 400 | 4 | 319.6 | 2.5 | 183 | 8 | 15.8 | - | - | 18 | 6 | 26 | |

| 2050M | M20×1.5 | 50 | 60 | 2500 | 400 | 4 | Threadless Type | 313.6 | 12.5 | 148 | 8 | 15.8 | 3 | 27 | 18 | 6 | 26 |

Basic Information

| Structure | Fixed Type | Nominal Mounting Screw [M] | 20 | Main Body, Related Components | Main Body |

|---|---|---|---|---|---|

| Orifice Type | Multi Orifice | Operating Environment | Standard | Body Material | STKM11A |

| Operating Temperature Range(°C) | -5::70 |

Specification/Dimensions

-

Stroke(mm)

-

Max. Absorbed Energy(J)

-

Max. Collision Velocity(m/s)

-

Thread Type

- Fully Threaded

- Semi-Threaded Type

- Threadless Type

-

type

- E-MSSTACD

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 10 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: How to select the product model quickly?

- Answer: Please refer to the models listed in the leftmost column of the web page to select the applicable thread diameter specification, stroke and maximum impact speed.

- Question: What are the advantages of two-way type shock absorber? What are its main applications?

- Answer: The economy series two-way type shock absorber has a unique double stroke structure, effectively reducing the installation space and trial cost; it is mainly applicable to high-speed automation industry, and can be used in manipulator, handling, conveying machine, etc.

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Kebijakan Privacy

Thank you for your cooperation.Terima kasih atas kerjasama anda.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Silahkan pergunakan Forms Permintaan.

Kebijakan Privacy