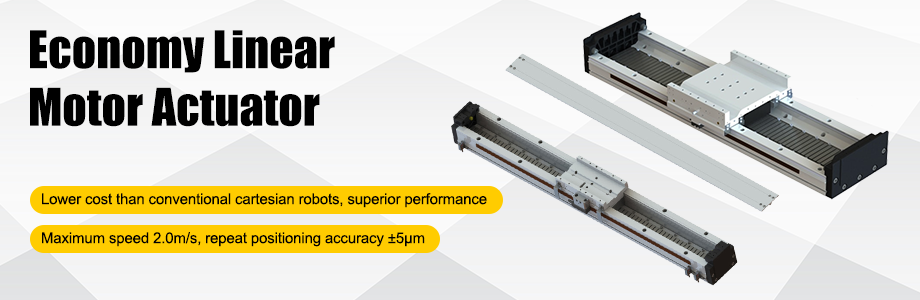

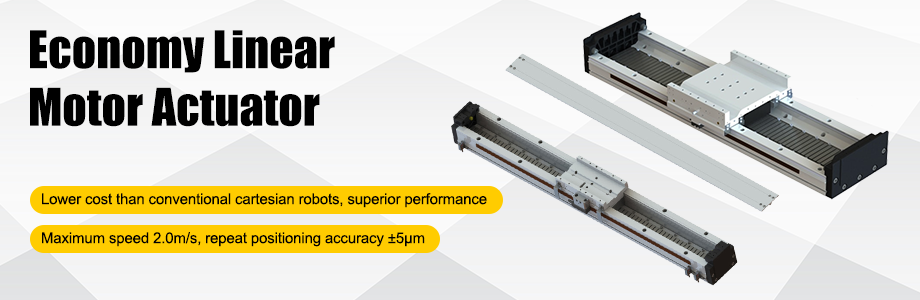

Economy Linear Motor Actuator

Lower price than existing orthogonal robots, superior performance

Maximum speed 2.0m/s, repeatable position accuracy ±5μm

Product Features

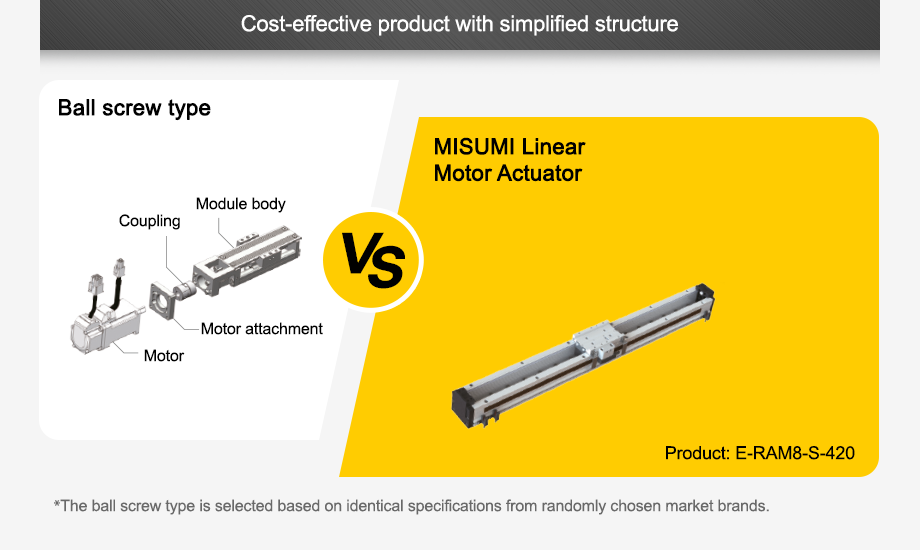

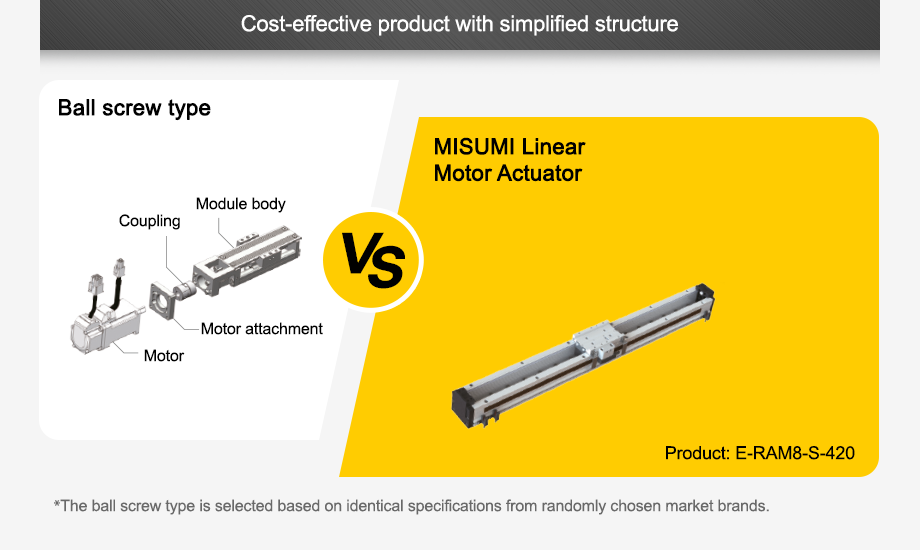

Cost-effective product with simplified product configuration.

Ball screw type: motor, coupling, module body, motor attachment.

Misumi linear motor actuator: 51% cost reduction through simplified product configuration Product E-RAM8-S-420.

※ Ball screw type is selected with the same specifications of a random brand among market products

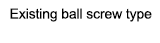

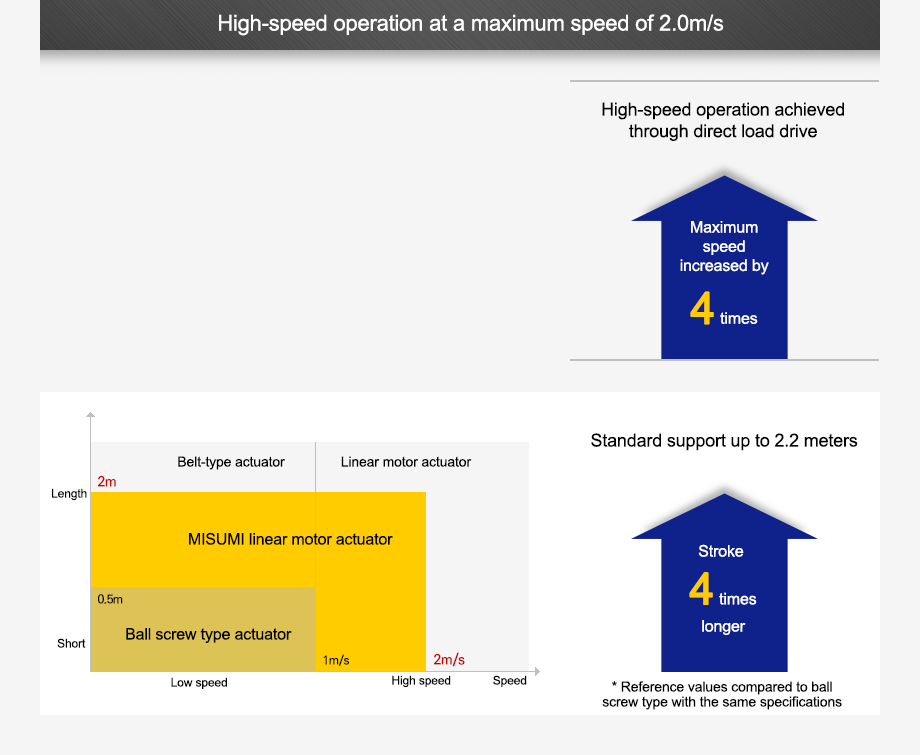

High-speed operation with a maximum speed of 2.0 m/s

Conventional ball screw type

Linear motor actuator

High-speed operation realized by direct load drive Maximum speed increased by 4 times

Stroke 0.5 m, speed 1 m/s Ball screw type actuator

Stroke 2 m, speed 2 m/s Misumi linear motor actuator

Belt type actuator, linear motor actuator

Standard stroke of up to 2.2 m 4 times ※ Reference value compared to ball screw type with the same specifications

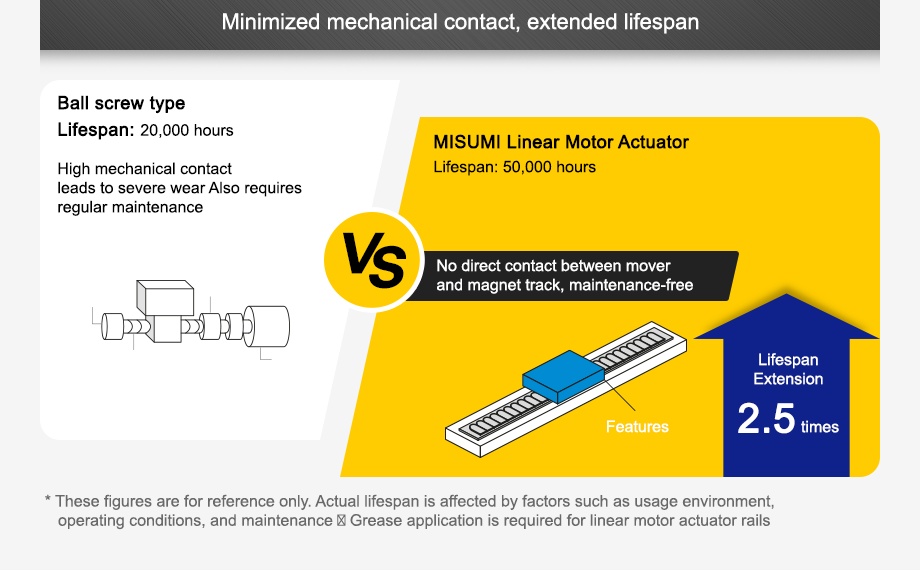

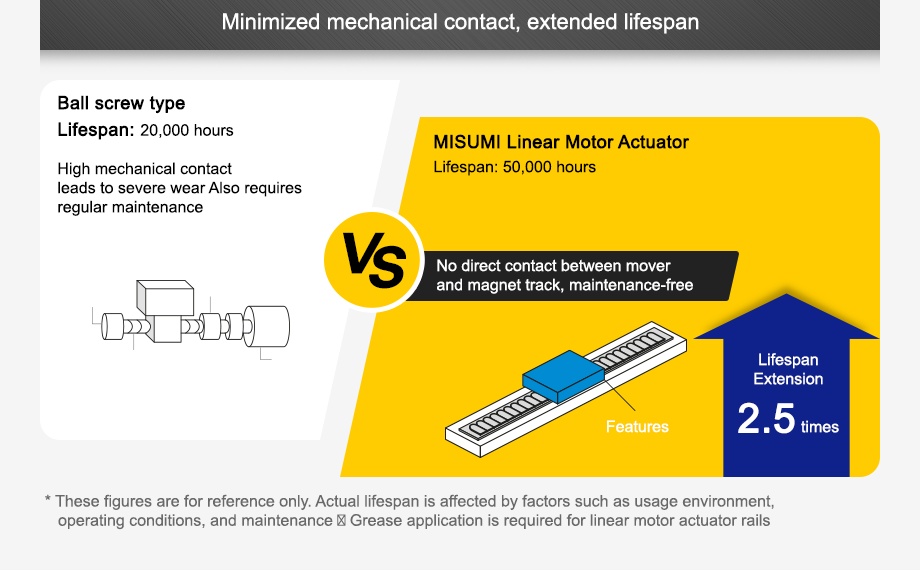

Minimized mechanical contact, extended life

Ball screw type

Life: 20,000 hours

Many mechanical contact points cause severe wear and require regular maintenance

Bearings, ball screws, motors vs Misumi linear motor actuator

Life: 50,000 hours

No maintenance required as the actuator and magnet track do not come into direct contact - no gap

Life extension 2.5 times

※ This figure is for reference only. Actual life is affected by factors such as the usage environment, usage

conditions, and maintenance.

※ Grease must be applied to the rail of the linear motor actuator.

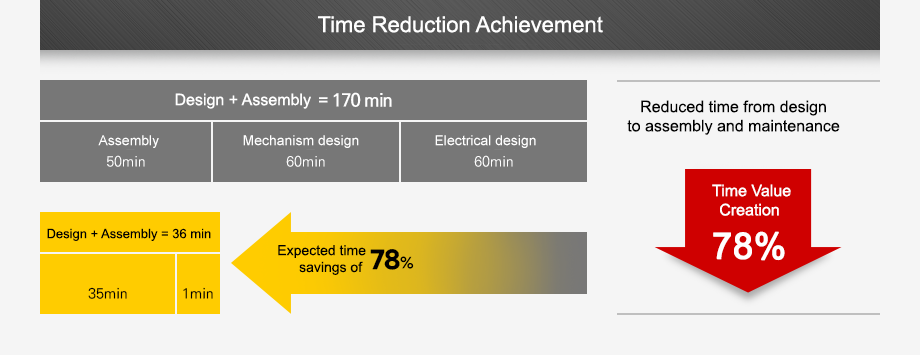

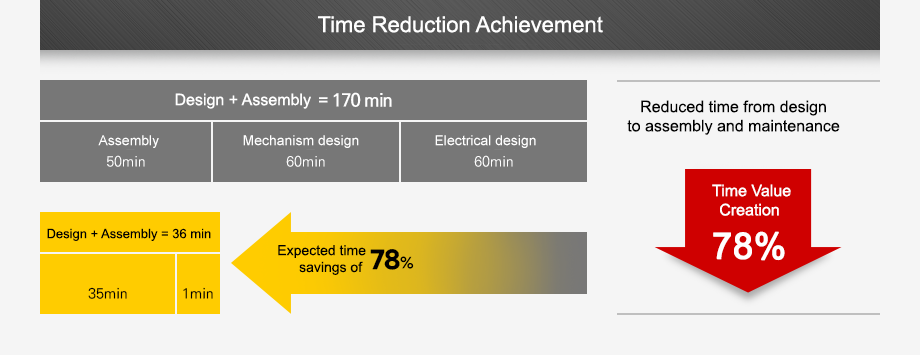

Realizing time reduction

Design + assembly = 170min

Assembly 50min, mechanical design 60min, electrical design 60min

Design + assembly = 36min

Assembly 35min + design 1min Expected time saving 78%

Time reduction from design to assembly and maintenance Time value creation 78%

Recommended Products

Note: Please check the current specification, price and delivery date again from the product page.

Economy Linear Motor Actuator

Economy Linear Motor Actuator  Economy Linear Motor Actuator

Economy Linear Motor Actuator